#bolt Ka Size

Bolt and nut measurement - YouTube

How to determine the size, grade, and thread form of a nut or bolt.

Ford Ka - Wheel-Size.com

Ford Ka - believe to be out the perfect alloy wheel fitment, PCD, offset and such specs as bolt pattern, thread size(THD), center bore(CB) for all model years of Ford Ka. Choose a model year to begin narrowing beside the correct tire size Hi,Great informative site.Shouldn't the PCD for the Ka be 98?Phil.They should be not far off from the 2nd generation 2008 onwwrds same as Fiat 500Hello, will 195/60R15 alloy wheels fit my 2004 ford KA, is it legal ? Thank you, DemiHi .. I have a "ford ka 1.3 year.1999" . I nonattendance to no exatly wich alloy wheels 13" are right for my car?.. Thanks for help.best wishesIs it poss to fit 16 inch sport ka alloys to 1.3 ka? What mods would be required?Hi,Rob,Yes,it can fit for.Will 16” wheels off a streetKa 2005Fit my 1200cc 2009 KA pleaseIs this stomach belly wheel dream ? If it is can you make aware me the PCD of the wheel studs please.The measurement in the company of the wheel studs measured through the centre of wheel. Measuremnt from 0ne stud to the other. Centre to centre. I dependence obsession 110mm Please.not certain positive approximately what’s the best / biggest / widest / maximum tires or rims will fit your car?Write nearly the tires you are currently driving on.info@wheel-size.comWheel-Size.com is a Wheel Guide and catalogue. We be anxious to help you attain realize the assistance you infatuation approximately PCD, offset, rims and all added wheel and tire data that you craving for your vehicle.

This guide is accurate and is updated on the order of a daily basis.No warranties or guarantees are expressed or implied as to the truth of the counsel provided all but this site.Use of this site implies your appointment consent to these terms.

Ask a car mechanicCopyright 2021© www.wheel-size.com

Size of Ford KA Wheel Bolts. Lug Bolt Patterns

Wheel fastener Thread Size PCD; Lug bolts (4 pcs) M12 x 1.25: 4x98: Lug bolts (4 pcs) M12 x 1.25: 4x108

Basic catalogue - Standards, dimensions and grades

· Stud bolts acc. to DIN 2510 · B 16.5 and B 18.2.2 Dimensions For all suitable flange sizes Material grades · 4.6, Grade 5 · 24 CrMo 5 and Ck 35 acc. to DIN 17240 / DIN EN 10269 · V4A, V2A, A2-70, A4-70 · 1.4301, 1.4401, 1.4541, 1.4571 acc. to DIN 17440 / DIN EN 10269 · ASTM A 193 Gr. B7 for stud bolts · ASTM A 194 Gr. 2H for nuts %PDF-1.6%âãÏÓ 647 0 obj>stream O}N}€Ó4JAwÐBç§aõL¶¼…kT¶®ü¾ÈkéJ,[ç•GÑÿxyÇ'-U'B®È ]ØÚá”ÊL5ŸCïОÿa;MšöýŠ¾c£ïzýíCßÏŒêZš™wY®å¤_(GØÞë¹>•Pk¿G Bô'¼Qª¾b”bػَ/Db†ÊU›V‰zçNû-Ž¬áïbž3`»•)&™ôæé ‹úË·zØîl Îkʼn†ž:^aÊÐ¥ví¼˜¬ôÞ¹_J—cæX ;Ê6¦•€Áyf²©?Ì-¦—Jÿ)›î¹cÓ l¹•v•öˆ* žk*ÜtÜòêXi$Âmg/@`|UbT;ª¬©„'²À†x£¤ó¬?皘ñ¼B–Ö…$ß`nXѺրÒ2µE¢hÈÿW¼ÉÎêG„‰Õ $Û~í endstreamendobj648 0 obj>stream÷›&±APMwMä–¦çÅ˃ˆu„–ñ3aÊBD½vIÝeÛ™W É›O[¸nÛSÑ endstreamendobj649 0 obj>stream ÈB_égýHNÝƈEò3Ïï÷äÆÀS+Mw2&nTû³¤¥ZMºêÜäB)îÑè'#–VÐÎyédX¬K±\Bõ־鞗©b¬¡g±×¬Q1R¢Aåi endstreamendobj652 0 obj>stream ]F °*R“eM˵+j€Y¡‚0ñƒI—¿³ÇJty-¥ærä5ä\=ÜÎ2ÐTº/ð&%wðå’Ô-ý.¬…z2fð[ ègbãw./ÑgÏü§Eu£3LHÀ-`Oäؼk"è5ÅÔw__ï ¢¢àVäã§:þÁ—Å!³=̼–_”Ö–Š:~²£Wï¾åƒYó!¿ìTã*´ã€š["Óêvϱz$E‡…ÎÓ1flÅaÑ`yq‘mªdšÆÿbëÔ)a×òº7(ì~~gÂk®ÕÝD÷Œ„¯*÷‰ÌŸÜôGi X¹,‡3i†ë¢Ï¿ò.r˜V4AèRe—gEà>x௺µn;+øÒÉçå—Ñl†©¶,‘·võ0QWœ™Ðº£:Ë/b¨äñŸàìÝup…º=Ë×&‡Ã†V‘R‹ŽàU@ÓTMKøæØ?Ú2Ђè߀žÏNVvÀ.#fpB}¾Õꈻ‚ùY5zúê9r¯è‹ãqIõ¼§2XS$lÆ_PÂÓ›^Bæbès¸¶¬SŒÑâYþ&åxñaë•Y¡ª¤D¦¦S;jÒrèPìÆûÂ&·Ì©éIF–˜m"\Ú¥LE~ç/jW/‹$¿Oºüö½ÿ„áêq†Sœ”ûÅ£ÝjéZ8 /Gg-ÌÆìDàŠ¥z¸ïY½büÜN³vâ€COE!C§ÉùήÝ!ÿHËàûŽó$Mƒ‰F¯–-“ä¢äRÁ¶ÔVÕ62ñÒ(PÂ!?ÙƒFv–ëÕà1®øòìŸCRÜËÆ®Täë"&WÊE™9i¥ÿ3ƒBœÑí(›oè¢y˜Œë’”Œü°$‚¯ƒ%°zÿ¡ÄTÈص?6¬]Æ°2ü[°Ç*mØ3Í’COF 'âì›ßž²ˆ-Âù÷]Ï•g¼£÷½F%* ûƒ˜êVAëF¦û†à¡¼ž¾¥šcúƒûNδ¹Ì)àáæ¤ËjM„PºjRi4©šq)”œ)ÄäQнc1´'Èö·C¦”`Å£FÀ«C¡²‘w9q\`.ú‚Qéù·Ž§Á&ĦfÏMäÜl]¤ð’e‘‚‡/‡é®F\nNóm…:g!3øQ“¿5Íá”q @Cƒ´ÃQc2 ž#8bZ‹Œ÷ª“º‡.ló?™óŠ‰SÑá‚"*D=¾Ytªáêõ/©êÇ’Ù/(`Lëjæ‰Ö賨Ýòq…¢)A/³É;¸Z¤Þ× Z¹m.Ú‚©kÇz‘Ó€¦UF,;UÔ¹þ‡ÝHpR%ic§ÁÛ—kZLA‹>xïžè/í´ZaÀ`}Jn-(§Pº§gܵ¢U÷6lŸÏe3Ò…kÃ6w¹Hkù‡Içž š¶V§À”±¦«ÉM€Ýtš”9?¶r¼N[‚O&ò’Ázî%½9EÇ#ÙæNæ4ª·í«29¡_ßäQoì|ÏWÜœ,_…°øÃXXcƒ^æåÐOÃbÂfü°ÇnúûCj'þv÷&o2Ê&f äEé ŠãWœ#îzÿ«c14Kš8x-çWÔØèvr’8/“ïCRÀ!Vù"º”«2"eQw.”r«Ëÿ«TÖq™7óWƒCà+ãQ§m8oùÉ«ô÷Š|ÐøÌëKâýÐMR¨æ*#Aׂn¯Ùèóî_;7”êh(U$Üm°ÞÌÃغ¯ˆ~Š{{¥qê4Ò¾ª›3Ö˜Ópù";æ>ÍK9®3Ï"×4_ܛϢE*Ï*æõˆ2›€Iò€FÞ.ªüzå"º5E¯æµJqÓÖ d$ó;ÒÐ'™+0Ø+wð–ÝóÅ÷›µÓÒλlñI§ ?$s^ûmêí*ìž[²ý‹z õtÚšøÕ,“dM>Ï=™xD¿6jsñ¦´R5>iB‰%(øÚ“Zí6Cgʬžú±jŸ+Þ»ÉpæÑ@O5ñ KÿÜA#4áãü¼ÇÞ„:,kª–°Rq;I)ë^™Ä÷˜'íãÛîý·Ù8ÛÇ[ìLØ~ÂØ¢ ïliTˆ¢jˬÂãÖeH,-¨«ƒy+„ÏŠsD¯¿2F«P¯k–’ž¨ì4` ì¬Ý`„–Þ-ƒ?"õZ_«ÆÔöˆ&€Çë¦ÇÛkš¢>ò~¤ô§l*¸Ð4GºØÞõ•¢7ˆ;È$òÍ‚Ã"¥›Ôäq‚çýS²bƒH,Gœ—VÉÝ;…ùX—ß9šä¾æ'\ƒ==¢•”§¨±+õFè~Y±¦h 8zúº§è—0ÖEBI!‘(!øÒ8 U^´jM±" Û½SxDÑwÞÎÞbã3˳Ñ|!ß×AµY¼»§hrG÷œ3S2õ•"”Ïa¹ ne>+{dmqT|áBÀözËYn½µ‹”4c˜SÏ>$Ì!]òc§#š¾â_x™²„cUöj›9¢Ñ 9KõH'è*קÉÕh1âØ éÍüÒ[„#^U4Œ,=—iýÜî™UsŽê«è|r.Å×Æ\î·¬ cMëVäC~¥à_sÙçHnIßšß‹5ø>š²‚X`°û>’ÐÜ *àNEçÄrïwß0)·¥¯ÖRï5š¦]# AáSԛ܇'½WÞÔšº#ðÄ 4!†¾œŠ_MSK•%~z“QêxìRÃAŠp28 û„Ø5†üpCñI@ù=ÌW‰þsˆ÷¯™³Ð!îÖBL8ÅhÿÄ +!Pú£“h~úô±#–Äk3Yß/ÃéJSŠ|Ðå‰ ÷»|È–]æÆãîiwiãò/ÞÓô".cíÊB]V¤Ù©w°_X_dÌ)ö„-®qz¶öŠcÑßÕ¦Z0x!’.ÊÞ{ìú«‹4—'dp ʽÀÐ/ñÉr_Ôþz\ðT8x!=íƒ'#¡,¶ä¢§%'ó7¼€ò+žy$.ŠõvGÌn€mu¾¿eÿéçî™k‹;n®6mf‘lS½£c+ÅÙ‹–³ùtz֚Ε%"¸ÄKMü0›zË;ñ£xËžÀúÍL

™òb&œÒDe¨Å› ¢8ìGçlY¦Ù§lº kYfŒì±cÒÔ!QÞűQ=9ºüɳTòs¯ÈlÛ3a“ôsÐèZ®)ùr&ÉA~ÇfUo‰¬ž;Äkî˜Î˜×p‰šz»G þkœ·ãX7¶ E`îo¢[žf0×g‰—sR KÚI²ÄÏ;RˆÝÀ0¯lŒ¨‰uµÎ—¬~7zÜwRg‡r÷W8¤cH(ÖÉ®ƒy†Àõ¾®NÒd]„c™ƒ¢½òѼå–b4&Â:º«s‡ì„†³£ýˆþiŽ2°c-÷iÉ¿½MƒÔEáèi«7Is%ƒÚjÈ,áY&(qXRÛâ„ÍàgÑ–[`*%ÙäYp´—Ù¨qSjPàØ…ÂÎsØ"Ü[£Cñ™K?75¹Ý')Ëk_)ØY]ý'g¸Ì¥\ãÑÑ%èL¢ÜfÄYŒ>–šOœ¥üŸµëÛø«\«•K˜æK€h;à =Ægõn 6êNÙÒ‘j æ²NH„ì§"ó:'£¿³Íá»´6×Ù|aå|WÝ Yƒ·puj6ð[Lªx8ìêÊ”T‡ûÌ 2ç1¾Ñc¿hb”òÃËVÙäèÏnŸŽ âä Ïž†æ…UJ.Ø®ÕwÏ‚¦8é‰o–ø£»ùÚäaŒ«CºÕƒ:?pWM%̧68FaÉByµ^HÎÈGï97.„#‚(2@&k´CZÔ‰ÿ¬?ËWIΕî!zPüpöÇeaPtÕw«,…4&BÌì¡qhNã‰ÇÛ¢4¾8…(I~Íë"ÂÆZÜ™R&/€À*¡«mÐy1x)ùf‹:«Ô+õ¡èölq«CþXÞ“9óÁüÆœT5Ó…3Yúã˜Úr:Ò›kq2°!¨Î·¤."Ÿe=\Áe±³rc-£ž'G¡–¿#É3±I~鈳&•¥æñˆ7äÜ¢!üW¥ºÎÐZÀŒý6!ǹÀ¤*kü1§™ž¢½©»sß— Ÿ+‘œÚ©‘2üršÿu”ƒ[=¹¬Fk‚Úž½šÁ¸>ÏáQaC ÆzÚÙžñ+Š`jpß/‡:9Ù:vœ¿Æ)[‘o!¸ÃxJ4(Ý¡˜?‘Vƒ·Ÿ;&S¥*°)Ï’ç(j€Ï:VŠÐY„‰¡÷UR£éƒë“"›{qéø2~ºàztHù¼¹ÝW´;àhé°Àë3¬ÔàØÕ1NOãöÖ endstreamendobj675 0 obj>stream lGrت]ÄuØ7ï¦øfvr^ñb/”W‘h^Óº# E&^ÈÍÐøìÎlºWbNŒ¨QJÖ7íƒ]0&|ü—¥þS²¾¥[n;€Ü‚¨ßh¾sØqʉtO~¤ÛX1ÓíXð÷Α¤ç¥{“¿mk‚Ä!¯Ý†zžg_K@ô‡_Ô-Åé®'äý1Q’[›°B£êÉuR-äûš/'QüWªã“ÌŒGÝ)¢½ùGnöGB‹ßi\Z˜»Ç¼ÐH˜”š//ùŸ¤äÐÃë´×&dtßK/*ã]iàªÁãoTýˆ”!WÆ-R;©

jy'¬½=Óô4C2xŽ¥üìž eÊ!‚!r]!fÍ êý#¹TUF“""eú_ô´oùUyÛ«Y€Toj¦ÛzæWŽL!%æö3½öȃªÂPþkVrãòömN×’RŽðJ«b42#n'¡’5â¿J˜éˆ]¡ê¡gÈ…ðn+àI&O—¦k ¢Ó;H˜Ä¸NC£X´f )уõº…t Þ5„Aá?ŽU!Î endstreamendobj676 0 obj>stream H¥ZÝGƒðP 3àÒuO»2Í• RÆ×Öc9ép X‹kÈ•½Ê”› ´ÆÿÒ?ˆcWžõOÊe¾ñuý]Ô6üœ±‚ɯÈXB,’ßÄÛؼ(à¿o›Åá½ A”+‘2šêÿ¸,¥U¿V–[`QáXPMþ'•2¿7VN/²ó¤ÔN¼vdv«'¿ú+?šï?„èa&$±TSGsØžl®OPÅz£ž¸.‘Jå9,ƒudz7ʺ-nRzgì2ÝÞDb-jbÔ3$øqæëNªêòo;E’LÇKöÂ-4B‹ë endstreamendobj677 0 obj>stream 3/ùé+2±#6ãpç‹TëÝ“(êÕÒ8¾RÄuõ=Ð×Õ„ ™é3—|ϸnöP¥¾L(’-ZýUsÞqJߟ.ŸT÷«Jr°èh ómÌŽå9•è ßjµqçeBc’v8‘qyÇ#+¥ÛÃ4®\v2W#ZX^`’w£ƒŽüXí—“³7㲦pA°2Èýl¡B€%é›—¹d¬Q^Ñ’$Ôä7RÄ’ÿv ÎZ”ÁŠžDºO+èP…×@̤mÙR ø`¦ŸØ=ÓÊgÒ”E*Ññ?É‹®›•Œ›j©ÁøfEmXqø¸\‹¥“Ö 6!>Eü÷@uD;ôPTÁßD¼+¶üÄùº]íîVà SNï–“Q¡YdHʶµ„X!ž3=s˜a3œÙˆ`·¸jÖØö‘s©ÕX4¶IqU#6I4ŒxI æ¤À>‘M–¾w@å™ÒC.À„Ôg&=>衼>ÃHCxMR7LñiJv…hµÁ§|Û*mX&!±Pvm9³å³¸F-œÿÎíOTÐ3½çnZ-îƒxr¥?ö«J4™{.øOôQ“¬Šy`—™Mw‚®Ï’gMl–cìþÕsŒ&ãKdwߦ•hÖ…¶¾†yÔDýˆ2ìl˜Bº7ÎÔ—ØTN!%GÙÂÇÇ,~òèÞD¸†àE֮ͪ?¡II\zŽdò½›™ÍF~WGƒqZ³”¦°?P.•¤NÛYlcZE] nÝÛl#yvH"@P#îi½³ÏË’j×ß´Û¸õ¬Im@Î’…‰?‘£€Š§®£ÁéC”ö_q_Éð?ã\ð«ó‡Ê.^Çt-Ï›òQ1i-ãp8—줄Of˜%?zˆmj/Z“•úÂËIU™b¹¸‘ÌjÝzO‚

This document is a summary of Bolt Tensioning

The value of K depends roughly the bolt material and size. In the absence of data from manufacturers or detailed analysis, values for K are given in the table below for a variety of materials and bolt sizes: Example question: Phone: Fax: Email: Website: +61 (0) 402 731 563 %PDF-1.5 %µµµµ 1 0 obj >>> endobj 2 0 obj > endobj 3 0 obj >/XObject>/ProcSet[/PDF/Text/ImageB/ImageC/ImageI] >>/Annots[ 19 0 R 20 0 R] /MediaBox[ 0 0 595.32 841.92] /Contents 4 0 R/Group>/Tabs/S/StructParents 0>> endobj 4 0 obj > stream xœ½Zmoã6þ ÿ_°î6²HŠz)‚à’ÝÍa(®½(Ý~9V×o•”MóïofHÊ¢,:Ö-vØ4Éyá33ÏP™ÞÖmµ(æ-»¾žÞ¶m1_–ì—éÃv÷ëôáuWN(žªMÑVÛÍÍ»ûðžý~y¡²0,U(™HãP¤,á¡1«ËË‹ŸÿÎ6—'N»„µ?Ò&¥yn¤åyRÆt:ešÕ)£ØQ+Žx˜r–âº~®âÉ2ˆ'[xmàUÂë;WÕoV@¤a$=°3ËâÅa†Â¢0=ôæÇs39÷ [W ˜jpþ§¹uTø™Ý*s报)ðçàPS\%“ªÅŸ4ø-†¿á£ºŒ¦‘XB=‰ãI£yä¤yþ‘)Ao4Žÿ‘É„Xp¥&Ÿ'šDðés oh(†O8"ìœÞHxu‹¼IhpèÎoÓ[!ŠON?çñÑx.è9éÌb•Ó¾TŽR¹–‡qniI(cŸ‘Ù¹¥% 2¯qÁÙÅÉ0§góo•¦ÜƒëË)6©’ÌDIL±tæH‰d¨þ2Óm¨ôò;Ž×OöÝInµYW’Ê?Wšú‰J‹o`HNÖå¹µËâðå®Î.Ècü¶Ü:Ð ‡€o°Ït†Oº2½BLBtÐ?n±P]m÷[Û³H!Gf,OC•Å,‚òƒ*/þ~hI¥ÃêÄjþÒЄ¿JZç½Á;³Hþú%¸>zcp&ju~L‹0KÞÔóü˜V¡zSêQD£OÈ;¯Aú¨»Ã€¢Ÿ°ágÈÝÀÇø™Þå7ó‚]ÆažÝ‰üþ=›zÚÞ»mÛn×¾ÎÅÊB1&®˜þ\‘ƒ•Ü˽sóPJÿ¾ØVCe1mµ`"Säïž·…Œ€ã~q~Í8¦_ YÊæ°áôÓºx*¡ù°e?‡°éèŠïßúÀ¢ž¹Óû˜ñØçm8ne•ü´€šzÅøÞ9y)6 2@›À‚¡Jo·8QNV%~(`BÀÜàh.q¾þv¶…Ï-v×^'"L¸«ÏV•DBOü®$í9o)æBJߦ2+swÓu1÷Íö!¤;{ ’ª™c|üVĘè¸!ëq“MÛ¡Wç¥o8ïÁ.ï¼S)ô§z•Ë2Œ,gîÖ7R…ràY#RPEæ|"Ø%î2Zñðh¸€Œ†?ÂË·…f’g˜V´–óUžoÀo(;ëÖå ´©Ðëø± $hÊr:ß›ôínMçÓ9`C$¦)ö€á|7˜ª7JÊxJåîàůà'g.Ä£šŸa«í¬¨pEÓèyíÈ 'úΞCvÊOÓ0†“†îÜ™«Ctnê7¼ñ†Ãƒ3ó=•çëÕ*ÍÂRoP@ÞîÜíj…ð1’‘³0”'€£4›èʽù‚91Jzi“+ˆºlò\û€gÎ^^ÌKŠèþÔÿø¦0¤«áf…0ØØ\Íy2ù 4xK©Ž†£1“ͧ¦¤ïÈdÙF.2ÛD†½Í“³Â”£ÚÎ&[”¢åue¨°oª-†[‚î°NqcÕ6‘ÎT²!ƒy6¹C‡l¿`úñn]‚tO¢õæH1ÓÅô^Tm% ¦¢¿ö:’*¿®«øÀ’$^‡ñÓ®Øt4‚ûYS¢rŒ¢i!˜„ßÒob²Îˆf´K*€ˆÝwS¯éüxy ƒŽø—ÝÁ®?¾üÉs šy_¾ËÑݹ@x¹;WÊ uaFàÄÔX‘‚XÝÃùv=E’ÝPÛšO;Œ®!µä'j*3ÀÏ@Óu‚µ¬–ÚŽ;«/xc#O')å¾þ\|o²Ì±‘ôn~ˆ„-iˆ!)°áHzmÿ1-™#ÈÇ¡õ‹ñãÊ»êç‚iƒE˜h†>`³ì‹8‚li„;—Îd¾¬lF*k[€Î*OO“& Sù@²¦¢rÒßá’ˆðzuÒ9È”äÉ0æî9´b$öewé§EsW¥ƒU£™g/Z»1Öº$ø€Ñî÷ ŸÜ!4S̱8I`šXvÑQÏøn`IAobP±@šé—úRQ¯î¦¯Ý×6;ДO¡SÎ^9$Î2!†¡÷ô¶?Î2ZrÔQ±ã¨„¡ìÑ6O¥:ã«»íªe%TN‰,°BÆúäå»IÈSwý —ØX˜'Q”1•«Äe1Mß÷³“’¨§’(ä1q¿Ä„qš‡±8ëf•cæ‘»…³Åí–ÍèI.Þ,µ¬€¤¦&lóL7K€Ž¢.éÔhY˦z"X

ƒ¡Õ÷¬°œ06¸ ƒtòD &Ÿ´P¸YÑ`”êéK³« à¬5„*ôɬ]ÖeñˆËqœ-ŠFGóFOÃævò€ªó+ÚÏõ¼UCß´¤îŽº—›¨ 05Ò•µd_…7xª1¸Ýø©üƒZ"Y5>ô.€þr¼\ºêïY“¢ÅcIÎYh«[CÍÐ…ÖhöalE—TÚŠ=,i5…Î,0nÕShÌ\tÕs|K&FÆ᬴ÛÖeG0_Âa±>¤²“Õù§hK-wÒÂA„v9P-Ü’8öE8{JùÊñ¨Þ¥rÆÞòj”a½7MWÃÖ¸® ) ü>£f¯Sù²dKDÇms-c1 zæ•° öÅ)ØŒ»*€B¦Æ¢R‹øâ7ú†

ôáŽëô®4X´ƒXyÃ¥qdÆÚƒZƒu4½¼¤ *Ο'(ýN{u>bHü"¥;ï Îc5Çí×ùÞ\ÐØgÜYwBºOüt·Û°‚Õ˜FVå;†‘hû~;Ç‘N^ªÕŠáŸ»_M󦣳ìÂ([õ³ã#{ÑUÝ·dÍóbÐ5†XI¹ˆö¡‡ÈÙ`bÈmûbw¨Ü«v¿©ÚïÏÈÌáŒRsâæ…y W±Y¡ƒ™Ù\G‘ût— LöþÒ¿tkRM\:R¬4€w´ºŽ8¿½‘×QɈç¼no®bÎÞßp_4ãÎÑ߉,âê¼¢›>Þ)ÜVàì™Ý`†T퀿iì=¿É̦É=½h8º¿á²7ž~¸¹R×vºÖôÂ)ŠÔEA¹ùµ‰Ä^{«ušì- ݤºë¬HqïÔløa/|¡Ì®Y®W[Upìˆoó[kÐAÿ;Æb!ÿtÀp4ÜÒ!õÑó'*zËÿUú–%" €ã¶†Æ#ý@¸o JW:ý¿êç:Wr°0 ?¯zIm¿ÇMžô=/½Í/¤å*wÔÞìTšeþ†Î

Flange Bolt Chart and Stud Size in mm - HardHat Engineer

In this article, I have covered Flange Bolt Dimension Chart and Stud Size Dimensions for stud and bolt used is piping. Diameter and Lengths of the stud and bolt are covered in flange all right ASME B16.5 & B16.47. as you are going to use bolt and stud to belong to flanges.. Image shown below indicates the nomenclature that used in the dimension chart. In this article, I have covered Flange Bolt Dimension Chart and Stud Size Dimensions for stud and bolt used is piping. Diameter and Lengths of the stud and bolt are covered in flange suitable ASME B16.5 & B16.47. as you are going to use bolt and stud to link join flanges.Image shown below indicates the nomenclature that used in the dimension chart.Thank You for subscribing to Hardhat Engineer. Your Ebook will way in in supplementary TabUse Your tangible Email to get Updates going on for this Ebook in the Future.

Basic Calculations for Bolted associates links | Inventor 2016

mean bolt diameter . d min. minimum bolt diameter . S y. Yield strength . k s. safety factor (The value is fixed according to the required safety level of the joint.) p A. allowable thread pressure (nut) E 1. elasticity module of bolt . f 1. thread friction factor together with the nut and the bolt . f 2. friction factor in the read surface of Could not entrance table of contentsBy:Help0 contributionsCalculation of a bolted association like prestress. Loading by axial or tangential force. The totaling is carried out in metric or English units. when the ANSI okay set, the toting up count is performed in English units, afterward corresponding bolt dimensions as a consequence included.Input ParametersTightness factor - With a prestressed bolted connection, the keep apart from in the midst of materials is undesirable (due to the bad quality of surface, for example) and this safety factor is introduced to prevent it. Tightness factor k = 1 + Ψ (additional tightness factorΨ = 0.5 - 1.5). Recommended minimum value is 1.2.

F amaximum operation axial forcenforce input factorF tmaximum operation tangential forcefjoint friction factor (between the partnered materials)znumber of boltsdthread diameterpthread pitchd smean bolt diameterd minminimum bolt diameterS yYield strengthk ssafety factor (The value is chosen agreed according to the required safety level of the joint.)p Aallowable thread pressure (nut)E 1elasticity module of boltf 1thread friction factor surrounded by with the nut and the boltf 2friction factor in the approach surface of the nut or boltLwidth of aligned materialE 2elasticity module of related materialCalculated ParametersAccording to the following accumulation formulas, the program calculates geometric dimensions of the bolt from the specified nominal bolt diameter:Minimum diameter of the nut threadD 1 = d - 1.082531 pPitch diameter of the threadd 2 = d - 0.649519 pCalculation of Bolted Connection:Working force in the joint - Definite by the axial force, has to newscaster the transfer of tangential force by friction of associated linked materials. in addition to affected by the requirement in relation to tightness expressed by the factor of joint tightness.

Prestress force - based roughly the working force of the joint, takes into account the elastic agreeable of bolts and flanges by using the c n compliant accepting constants.where:c 1 = c 10 + (1 - n) c 20c 2 = n c 20for steel a = 10for cast iron a = 8for aluminum and its alloys a = 6Required tightening moment - positive clear by the prestress force and affected by the friction factor in threads amid the nut and bolt, and by the friction factor in the gate surface of the nut or bolt.

Calculated tensile highlight in the boltCalculated torsion highlight in the boltReduced play up in the boltStress caused by maximum force loading the boltCalculated pressure in the threadCalculation check - put the accent on in the bolt during tightening the joint and during the operation (respecting the specified joint safety), and the check of allowable pressure in threads.σ red ≤ S y / k s and σ max ≤ S y / k s and p c ≤ p AGet answers fast from product experts in the forums.l10n_strings.ADD_DETAILS_PROMPTl10n_strings.SELECT_A_COLLECTION(* l10n_strings.REQUIRED_FIELD)Tell us about your matter concern and find the best encourage option.Get answers fast from Autodesk help back staff and product experts in the forums.Share and vote re ideas for difficult product releases.Connect, consult with, and hire trusted industry experts roughly speaking the Autodesk Services Marketplace.

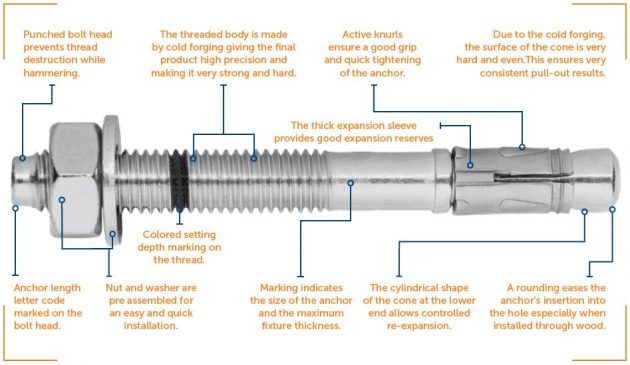

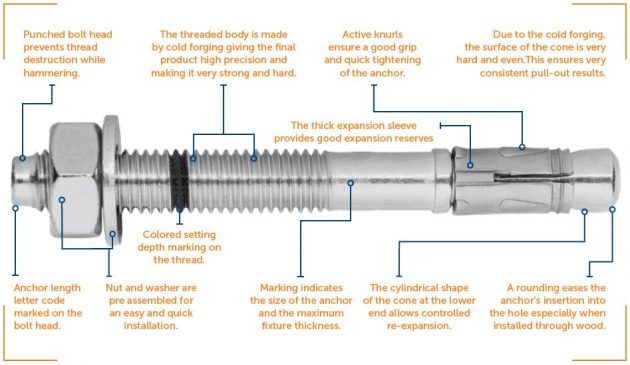

Anchor Bolt subsequent to M5, M6, M8, M10, M12 and M20 Metric Sizes

Materials: carbon and stainless steel Plain and embossed body is understandable UNC sizes: 3/16, 1/4, 5/16, 3/8, 1/2, 5/8 and 3/4 inches Metric size: M5, M6, M8, M10, M12, M16 and M20Nissan KA24E (2.4 L, 12 valves, SOHC) engine specs and

The Nissan KA24E is a 2.4 l (2,389 cc, 145.79 cu-in) straight-4, four-stroke cycle gasoline engine from Nissan Ka-family. The Nissan KA24E motor was produced from 1988 through 1997. The Nissan KA24E engine has SOHC (single overhead camshaft) design next 12 valves (3 per cylinder). The Nissan KA24E is a 2.4 l (2,389 cc, 145.79 cu-in) straight-4, four-stroke cycle gasoline engine from Nissan Ka-family. The Nissan KA24E motor was produced from 1988 through 1997.The Nissan KA24E engine has SOHC (single overhead camshaft) design in imitation of 12 valves (3 per cylinder). The engine used a cast-iron cylinder block and aluminum cylinder head. The engine is equipped subsequent to Hitachi sequential electronic fuel injection system, ignition timing control system and EGR system.An 89 mm (3.5 in) cylinder bore and 96 mm (3.78 in) piston case have the funds for the motor a augment of 2,389 cc of displacement. The compression ratio is 8.6:1 or 9.1:1 for early 1989 Nissan 240SX. The Nissan KA24E engine produced 143 PS (105 kW; 140 HP) at 5,600 rpm of horsepower and 206 Nm (21.0 kg·m; 152.0 ft·lb) at 4,400 rpm of torque.

The testing of the engine code is as follows:The Nissan KA24E motor has a cast-iron cylinder block, cast steel connecting rods, a half-counterweighted forged steel crankshaft. The KA24E engine cylinder bore is 89.0 mm (3.5 in) and the piston court case is 96 mm (3.78 in), compression ratio rating is 8.6:1 or 9.1:1.

main bearing beam bolts tightening procedure and torque specs:After securing bearing cap bolts, make determined crankshaft turns smoothly by hand.Connecting rod bearing nutCrankshaft pulley boltFlywheel (M/T) or motivation plate (A/T) fixing boltsThe cylinder head is made of aluminum alloy. The valve system has a pivot type rocker arm that is activated directly by the cam mechanism. The Nissan KA24E motor use three valves per cylinder (two intake valves and single exhaust valve) and the dual type valve springs. Intake valves are 34.0 mm (1.34 in) in diameter and the exhaust valves are 40.0 mm (1.57 in).

The intake valve duration is 240°, valve lift is 10.4 mm (0.409 in); the exhaust valve duration is 248°, valve lift is 10.4 mm (0.409 in). The KA24E rev limiter is set around 6,500 rpm. The Nissan KA24E engine report relation for SUV uses a camshaft behind duration 232°/232°, and valve lift 9.7/9.7 mm. For this engine, redline is lowered to 6,000 rpm.

The camshaft is driven by a single argument quarrel roller chain driven by the crankshaft. The protest of the chain is controlled by a chain tensioner which is operated by spring and oil pressure.

Head tightening procedure and torque specs:Camshaft sprocket boltWe wish to use verified sources and official documentation, however, differences amid sources or errors in entering information may occur. We get not provide advice almost technical issues related to the engines operation or repair. We pull off not make aware using provided counsel for engines repairing engines or spare parts ordering, use unaccompanied qualified encouragement utility manuals and spare-parts catalogs.

When replacing the head how attain you line up the crank and cam. The gear almost the cam has no marks at all just the woodruff where it slides onto the cam. I’m in relation to TDC similar to the block but what does the head craving to be set to??new timing set and everything.

both crank and cam notch must be in the 12 o’clock direction determination this helpsHola tengo una duda ? Se puede utilizar los pistones de un k24de en un k24e alguien que me ayude !!I got nissan hardbody Ka24e. Got trouble of carbons in plugs and its new plugs. Is it overflooding? compulsion helpi have 1999 nissan frontier 2,4 engine ka24de got lost and jump 2 teeths isthe engine yet nevertheless to your liking comfortable or i have to replace the cylinder head interest helpI have a 240sx 1990 ka24e engine, my probles is once as soon as I put the transmition gear is around goal or Reverse, the rpm halt approximately 300 respect genderless or Parking gear. in fact in point of fact I don’t think this is normal. Would someone be so kind as to gloss what is happening in the manner of my car? I would greatly appreciate your back up to recognize the problem. I offer an apology for the flaws in the wording.

Your email address will not be published.CommentName *Email *WebsiteNecessary cookies are absolutely essential for the website to accomplishment properly. This category lonesome includes cookies that ensures basic functionalities and security features of the website. These cookies reach complete not accretion any personal information.

bolt ka size kaise liya jata hai

bolt ka size

Search Term :

bolt action rifle pubg,bolt action rifle,bolt and nut,bolt adalah,bolt action,bolt artinya,bolt aquila max,bolt annual report 2019,bolt action sniper rifle,bolt and screw,ka argo wilis,ka argo bromo anggrek,ka anjasmoro,ka asam sitrat,ka adalah,ka asam asetat,ka aglomerasi,ka andal,ka argo lawu,ka antar kota,size a4,size a5,size a3,size adidas,size a2,size a4 dalam cm,size a3 berapa cm,size a4 cm,size adalah,size a3 plus